In order to improve crawling efficiency, we started to develop controllable grippers for the caterpillar robot. There are three common mechanisms for gripping: Hooking, Adhesion, and Suction. For the scale of our robot, micro-hooks array and adhesion pads seemed most probable. Manduca caterpillars use the former(crochets) while most insects employ both. However, there are great challenges in both systems.

To effectively dig into substrate of non-uniform stiffness, the micro-hooks array has to vary in hook size and compliance. Up to date, we have very little knowledge about these hooks arrangement and properties. Let alone the task of manufacturing such an micro-array for load bearing.

On the other hand, sticky pads are easier to produce. There are hundreds if not thousands of different adhesive materials to choose from. However, release of sticky pads may be quite a challenge for small robots.

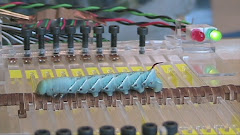

After evaluating the situation, I decided to design a membrane with sticky substance on it. Once I master how to control such a membrane, I could control the sticky pads. Then, micro-hooks array can be incorporated into the system.

Subscribe to:

Post Comments (Atom)

.jpg)

What a tough job!

ReplyDeletePut a translation in Chinese for my friends:

為了提高攀爬效率,必須為機器毛蟲開發可控的爪鉗;有三種常見的抓握機制:鉤子、粘著、吸附,針對我們機器蟲的尺寸,微矩鉤和粘著墊似乎是最理想的,〈煙草蛾幼蟲〉使用前針編鉤,而大多數昆蟲都混用這兩型抓握機制。無論採用那個系統,都是很大的挑戰。

為了有效地鉤入軟硬不一的接觸面(非均勻剛度),必需採用多組不同長短鉤著及型式的〈微型矩鉤〉。到目前為止我們對這些掛鉤的安排和特性暸解的不多,更不用說製作這種能承重的〈微矩鉤〉。比較起來,〈粘著墊〉是更容易產生的,有成千上萬不同的粘合材料可以選擇,但是對於小型機器人,黏著墊拆裝具有很大的挑戰。

評估有關情況之後,我決定設計〈粘性膜〉,一旦掌握如何控制這樣的膜,便可以控制〈粘著墊〉,然後,再把〈微矩鉤〉納入〈粘著墊〉系統。