Dear readers,

If you see this message, then I must thank you for your loyalty to my blog. I apologized for missing out almost a month of blogging, but really I can't afford to get into trouble. In any case, welcome back to my rapid pace of locomotion research and biomimetics. Currently I have two robotic lineages: InchBot[7 generations] and GoQBot[4 generations]

Each robot generation has a very specific research aim and target performance. I think it's time for me to present them to you in a video format. While all the videos have been edited and annotated, I still need to link them from the Tufts Media Server. Please be patient! They are coming soon.

Sunday, October 18, 2009

Sunday, October 11, 2009

DARPA Review

It's peculiar how things evolve. I never meant to get into this DARPA project until I realized how far I've been sucked in. So here I am working on my robots in the second room of Biomimetic Devices Laboratory every minutes of my awareness.

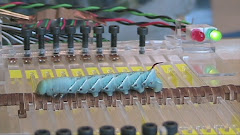

It's peculiar how things evolve. I never meant to get into this DARPA project until I realized how far I've been sucked in. So here I am working on my robots in the second room of Biomimetic Devices Laboratory every minutes of my awareness.System engineering requires a lot of collaboration but creation really has to be solo. A roboticist has to be able to work with people as well as alone. I was fully aware of the importance of this final review, because a lot of people depend on this funding at Tufts, including many friends and colleagues. For me, that's enough at stack even if I had alternative funding source for my primary research. I simply had to do everything in my power to make this robotic demonstration rock solid and fail-proof. I was really up for the job!

In September, I produced a plan for preparing this robot demonstration. Following is a rough list of the issues we had to consider:

1. Transportation protection

2. Demonstration platforms

3. Displays cases and proper Logos

4. Portable power supply and charging units

5. The robots (obviously) and their doubles

6. The control system and a secondary backup

7. Primary robot operator, backup operator

8. Demonstration program and rehearsal

9. Robot specification data

10. Backup video shots in case some live demos fail

11. Tool boxes

This list just went on... My job was to coordinate the designs, search for the parts, arrange the purchases, find appropriate help, and do as much as possible to complete my robots and their accessories. In a typical day, I would spend 5+ hrs doing micro-soldering and bonding, 2+ hrs programming, 2+ hrs literature research, 3+ hrs robot testing, 2+ hrs casting/molding. On top of that, I had to purchased about $500 worth of components everyday on average. Actually, I found shopping the most stressful task among all. In order to get the right thing on time, I had to check the mechanical/electric compatibility, availability, pricing, shipping, and make payments. That's probably why R&D companies always have a person or a group of people specifically do purchasing. It's such a tough job.

Anyways, it's Sunday night now! We are up for the show in two days. I better get some sleep and hope for the best.

Subscribe to:

Comments (Atom)

.jpg)