Tuesday, April 26, 2011

The rise of "soft robotics"

Almost 5 years ago, I finished my B.A. in a hurry to plunge myself into the research of animal locomotion. As I accepted Tufts' Ph.D student position, I knew that I was caught in a wave of modern robotics innovation. Five years ago, "soft robotics" is a funny term. Even today, roboticists still debate what soft robots really are. In any case, "soft robotics" has transformed from a crazy talk to becoming an active field of research in the past few years. You will hear a lot more about soft robotics this year from me and from many other research teams around the world.

What really triggered this movement is not really clear. But I would venture to say that the DARPA ChemBot project certainly motivated and cultivated the first generation of soft roboticists in the United States. Many Ph.D students PostDocs alike were supported by this program to pursue soft robotics in many aspects. I was one of them.

Although I have received my Ph.D at Tufts and am now working as a postdoc at Harvard, I will continue to blog about caterpillars and soft robots as long as I am still publishing my thesis work throughout the summer. Beyond that point I will probably have to decide where to begin telling a new series of stories about my new pursuit in animal flight.

It's just the beginning!

Sunday, March 27, 2011

Caterpillar acoustics

I have been trying to write a new post with real scientific materials in the past two weeks. Frankly, it was very difficult to decide where to start after such a long break. In any case, I finally decided to start with a literature review about acoustics in caterpillars.

Yes, some caterpillars do make sounds and use acoustics for communications. Sounds are essentially mechanical vibrations transmitted via some medium. Any organism capable of creating vibration has the potential to transmit information acoustically. In recent years, acoustic communication has become one of the hot topics among the caterpillar biologists. We know that soft tissues are extremely good at absorbing vibrations. How do caterpillars make a sound with such soft bodies?

Well, there are a number of rigid parts in caterpillars where significant vibration can be generated. For example, the mandibles (the mouthparts) are made of tanned cuticle (chitin composite). They can be as hard as some aluminum or carbon-fiber reinforced polymers (Vincent 2004). To signal territory, cherry leaf roller caterpillars (Caloptilia serotinella) scrap their mandibles across the leaf surface to create vibrations on the leaf. Sometimes, plucking the leaf would be sufficient to generate the vibration. These behaviors are observed more frequently when a conspecific (another caterpillar) stumbles onto the leaf roll (Fletcher et al 2006). Some direct body vibration was observed in these caterpillars but with much rare occurrence. Most acoustic signals are still generated by working the hard mandibles against the substrate.

Alternatively, caterpillars can drag their rear ends across the leaf to produce vibrations. Yes, “anal scraping ” is the technical term used in the original literature that reports this behavior (Yack et al 2001). As much as it sounds indignant for the caterpillars, the methodology is quite effective. Larvae of the hook-tip moth (Drepana arcuata) develop a pair of modified oar-like setae instead on their anal segments (they do not have terminal prolegs). These stiff “anal oars” are less than half a millimeter and bit into the leaf as the animal drag the anal segment across the leaf surface to produce relatively long and audible noise (Bowen et al 2008). Such adaptation has been observed exclusively in the family Drepanae, and it can be shown that the anal oars are derived morphologies in these small leaf-rollers as a special adaptation (Scott et al 2010).

The acoustics in caterpillars continue to make headlines. In February, the Journal of Experimental Biology features a research article reporting whistling behaviors in caterpillars. Again this is not a metaphoric description but an illustrative one. Caterpillars of the North American walnut sphinx (Amorpha juglandis) can produce sounds by expiring forcefully through the spiracles (caterpillar’s air valves) (Bura et al 2011). When a caterpillar contracts forcefully, the body compression can squeeze air out of the tracheal system. I reported this phenomenon in one of my earlier posts as I put crawling caterpillars under water. In the walnut sphinx, however, the spiracles of the anal segment are elongated to produce wider lips for whistling. The caterpillar produces three types of audible acoustic signals in response to simulated predation and effectively startles an attacking bird.

The diverse morphologies and behaviors of caterpillars continue to amaze biologists in different contexts. For caterpillars that are vocal, they certainly have expanded their abilities to relay signals important for survival.

Caterpillars, make some noise!!

References

Bowen, J. L., Mahony, S. J., Mason, A. C. and Yack, J. E. (2008). Vibration‐mediated Territoriality in the Warty Birch Caterpillar Drepana Bilineata. Physiol. Entomol. 33, 238-250.

Bura, V. L., Rohwer, V. G., Martin, P. R. and Yack, J. E. (2011). Whistling in Caterpillars (Amorpha Juglandis, Bombycoidea): Sound-Producing Mechanism and Function. J. Exp. Biol. 214, 30-37.

Fletcher, L. E., Yack, J. E., Fitzgerald, T. D. and Hoy, R. R. (2006). Vibrational Communication in the Cherry Leaf Roller Caterpillar Caloptilia Serotinella (Gracillarioidea: Gracillariidae). J. Insect Behav. 19, 1-18.

Scott, J. L., Kawahara, A. Y., Skevington, J. H., Yen, S. H., Sami, A., Smith, M. L. and Yack, J. E. (2010). The Evolutionary Origins of Ritualized Acoustic Signals in Caterpillars. Nature Communications 1, 1-9.

Vincent, J. F. V. and Wegst,U.G.K. (2004). Design and Mechanical Properties of Insect Cuticle. Arthropod Struct.Dev. 33, 187-199.

Yack, J. E., Smith, M. L. and Weatherhead, P. J. (2001). Caterpillar Talk: Acoustically Mediated Territoriality in Larval Lepidoptera. Proc. Natl. Acad. Sci. U. S. A. 98, 11371.

Thursday, February 17, 2011

Huai-Ti's Ph.D and beyond

I apologize for the lack of update for such a long time. In the past 5 months, I've been busy with publications, thesis and postdoc interviews. I have successfully defended my thesis on January 26th and am now starting my first postdoctoral research at Harvard University. Many colleagues inquire whether I would keep on blogging. The answer is yes, as this is my major contribution in science outreach. However, given the among of sleep I've been missing and the number of duties I have, I could probably only update once a month.

In the world of scientific research, the researchers are "the projects". There is no way to separate "work" from what people call "life" because research is part of a scientist's life. In fact, it is what makes a scientist "a scientist".

Sincerely

HTL

Sunday, September 19, 2010

My primary Ph.D projects

My first project at Tufts was to design a force beam array to collect ground reaction forces from all the leg contacts from Manduca caterpillars in two directions simultaneously. This system involves synchronized video tracking and alternative force transducer design. The results suggested that caterpillars may use the substrate to transmit force much like an external skeleton. I'm currently working on the manuscript for the second part of the animal study.

For soft-bodied animals, tissue material properties can contribute greatly to the overall behaviors. My second project at Trimmer Lab was to instrument a lever-arm system to perform uniaxial tests on soft cuticle from the Manduca caterpillar. These soft specimens were often 5mm long and less than 1mm wide. Real-time video extensometry was necessary to control the strain. We then attempted an constitutive model for the material.

To understand how tissue mechanical properties affect the overall animal behaviors, one must go to the structural level. My third project was to investigate the overall structural properties of the Manduca caterpillar over a scaling range. We tracked down all the body tissue that could take mechanical loads and simulate the hydrostatic skeleton in a FEA model. We found a dramatic increase of flexural stiffness associated with body miniaturization. This implies several evolutionary constraint on caterpillar body plans.

Going beyond the Manduca crawling, I wanted to explore some clues about how caterpillars developed inching gaits in the course of evolution. I first simulated different crawling and inching gaits in my first soft-bodied robot lineage. Then I created a second robot lineage to simulate some ballistic behaviors which were supposed to derive from the normal locomotor patterns. Finally, I conducted a field work in Costa Rica to examine all these caterpillar behaviors in nature across different species.

In summary, my practical skills in the lab allowed me to design systems, acquire all the parts/supplies, manufacture/implement devices, and program systems to execute experiments. I would summarize my scientific contribution in my little niche in three statements.

1) During locomotion, soft-bodied animals can use the substrate as their external skeleton, and therefore gain stability and robustness.

2) The mechanical scaling of hydrostatic skeleton may limit the prolegs configurations and locomotor modes in caterpillars.

3) Soft-bodied robots, by definition, cannot rely on exact postural control. The very minute such a robot force a conformation, it becomes rigid.

Wednesday, September 15, 2010

Mechanics of a ballistic roll - Part 2

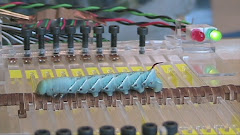

Kinematics tracking can be very tricky especially with high speed erratic movements. In order to compute the angular momentum of GoQBot, we must know the mass distribution of the robot as it deforms quickly within the 0.2 second window. One way to do it is to break down the body into many segments and track each segment individually. However, that requires installing more than twenty 1-mm size IR emitters on a small soft body no longer than 12cm. The soldering would be simply a torture, not to mention the wiring. Luckily, there is an alternative: kinematics-based model extrapolation.

Kinematics tracking can be very tricky especially with high speed erratic movements. In order to compute the angular momentum of GoQBot, we must know the mass distribution of the robot as it deforms quickly within the 0.2 second window. One way to do it is to break down the body into many segments and track each segment individually. However, that requires installing more than twenty 1-mm size IR emitters on a small soft body no longer than 12cm. The soldering would be simply a torture, not to mention the wiring. Luckily, there is an alternative: kinematics-based model extrapolation. The idea is to constrain a virtual model of the GoQBot using the five IR-marked coordinates as the reference. By applying some deformation characteristics on the model, I can easily extrapolate the positions of every bit of the robot. This is exactly what I have done.

The idea is to constrain a virtual model of the GoQBot using the five IR-marked coordinates as the reference. By applying some deformation characteristics on the model, I can easily extrapolate the positions of every bit of the robot. This is exactly what I have done.

Monday, September 6, 2010

Sharing research tools and links

A new section has been added to my blog called "Huai-Ti's research tools". There you would find some useful links from general referencing to good online stores. There are also some good deals such as a free SEM imaging program (but the image will be public). In addition, you may find some useful software for making presentations or publications. For example, there is a Screen Capture Software that streamlines the print-screen function in most computers. Anyways, stuffs like this could be useful when you need it. I will populate this list gradually.

Over the past four years of my R&D, I have designed over 12 instruments, written more than 5 systems of feedback control programs, placed more than 85 orders for supplies and parts. I guess the number of projects and pet projects in experimental science directly correlates to the spending and instrumentation. Also, people in my research team tend to leave purchasing jobs to me since I've been really good at communicating with vendors and company associates to get the right parts for laboratory research. But I have to say such job is really stressful, although all the spending came from various research grants and not from my pocket.

Friday, September 3, 2010

Mechanics of a ballistic roll - Part 1

First off... I would like to remind you of the behavior that I'm studying. See the ballistic rolls and flips in some leaf roller caterpillars, and check out my biomimetic GoQBot's performance.

First off... I would like to remind you of the behavior that I'm studying. See the ballistic rolls and flips in some leaf roller caterpillars, and check out my biomimetic GoQBot's performance.To study the the dynamics of such impressive behavior, the robot has been a great tool to test hypotheses and facilitated the collection of mechanical and control data. Back in April this year, I successfully collected the kinematics of GoQBot using my own adaptation of the VICON motion capture system. However, the kinematics data alone only tells half of the story. We could compute the angular momentum as well as the linear momentum from pure motion tracking. However, there is no data on the mechanical power output and loading condition. To extend the analysis, I took one of the force beams I used for caterpillar ground reaction forces measurement and implemented it for robot GRF collection. In fact, VICON system has built-in capabilities to take in force-plate measurements and any other analog signals.

With some modification and instrumentation, I obtained GRF in two directions from the head anchor and simultaneous recording of the actuator current draw during the high speed kinematics recording. Here are some very preliminary data.

With some modification and instrumentation, I obtained GRF in two directions from the head anchor and simultaneous recording of the actuator current draw during the high speed kinematics recording. Here are some very preliminary data. I'm currently processing the data to calculate the center of mass and the development of angular momentum. More results are coming!!

I'm currently processing the data to calculate the center of mass and the development of angular momentum. More results are coming!!

.jpg)